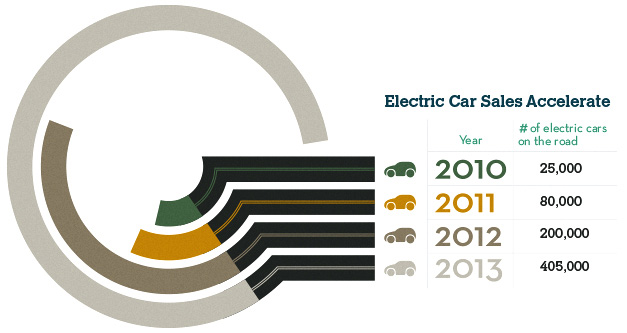

Globally, at the end of 2010, there were 25,000 electric cars on the road. At the end of 2011, there were more than three times that amount: 80,000. At the end of 2012, there were 200,000, two-and-a-half times more. And at the end of 2013, there were 405,000.

Translation? The number of electric cars on the roads has been doubling or tripling every year for the past several years. Although electric cars represent just approximately one percent of the automobile market, the growth trend is similar to what we’ve seen for every other disruptive technology: washing machines, dishwashers, computers, laptops, cell phones, smartphones, cassette tapes, CDs, MP3 players, and digital cameras, to name a few. From a certain point of view, we could say that electric cars are about halfway to market domination.2

Not every technology that starts out strong ends up taking over. These first several years of electric car growth follow the disruptive technology pattern, but they don’t guarantee an “electric vehicle revolution,” as many in the industry refer to it. For a technology to replace another so completely, it needs to be: 1) much better, 2) cheaper, or 3) both. You aren’t going to buy an electric car simply because other people are beginning to do so. You’re going to buy an electric car because it makes much more sense for you. I’m convinced that for the average person, this time will come – this year, next year, or sometime in the coming decade.

Convenience

Whether we like it or not, we are a convenience-based society. So many of our products and services are based around convenience, and that’s true for electric cars as well. How much time do you spend each year going to the gas station, filling up, paying, and getting back on the highway? With an electric car, all you do is plug in when you get home and unplug when you are ready to leave.

Unfortunately, there’s so much hype about the shorter range of electric cars on a full charge compared to gasoline-powered cars on a full tank that an outsider might have the impression that electric cars are less convenient. But very few people drive 80 miles in one day on a regular basis. In the few instances when you do drive that distance, renting or swapping a car is an option.

In discussions about limited range, affordable electric cars such as the Nissan LEAF are often cited as an example. The situation improves if you can afford a Tesla Model S, widely considered the best mass-manufactured car on the market, gas or electric. For those of us not in the luxury car category, the technology is quickly improving. In a handful of years there will be many electric cars available that will have a range of up to 200 miles.

Convenience goes beyond charging. Electric cars have very few moving parts and their motors are much simpler than gasoline engines. Forget oil changes (not needed), busted tubes and valves (not used), muffler problems (nonexistent), smog checks (zero-emission vehicles are exempt), brake problems (regenerative braking helps your brakes to last much longer), and transmission problems (no transmission, no problems).

Pleasure

The other big seller is pleasure. To my mind, there’s no doubt: electric cars are much more pleasurable to drive. They are extremely smooth and quiet, and electric motors are about three to four times more efficient than gasoline engines.

But the best part about the performance of electric cars is what’s called instant torque. Even if an electric car and a gasoline car have the same 0-60mph rating (for example, seven seconds), the electric car feels much quicker because of that initial burst. It’s termed the "EV smile."

The smooth ride makes driving fun, but also easier and less stressful. The most nerve-wracking aspects of driving are when you have to accelerate onto a highway with fast-moving vehicles, turn across a few lanes, or accelerate into a roundabout. The instant torque that electric cars offer lets you do all of this much more quickly and easily. This, along with the convenience factor, is what will sell electric cars to the average person, once they do a test drive and realize what these modern vehicles offer.

Money

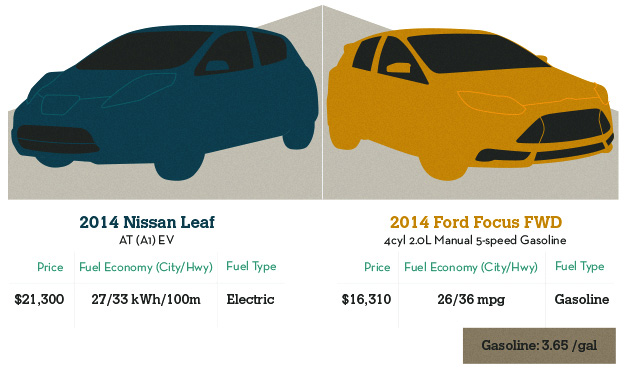

Time is money, so the massive time savings you get from not having to go to the gas station, in for an oil change, and to the mechanic will amount to a great deal. However, electric cars actually save you literal money. They are approximately three to four times more efficient than gasoline-powered cars. The most efficient hybrid on the U.S. market, the Toyota Prius, gets 50 mpg. The most efficient electric car on the U.S. market, the BMW i3, gets 124 mpg equivalency (mpge). The average new car in the U.S. gets about 25 mpg. The most popular electric car, which costs a little bit less than the average new car before any financial incentives, gets 114 mpge, making it four times more efficient than the average new car. (The average new car costs a little over $30,000, while the Nissan LEAF costs $28,800 before any financial incentives, $21,300 after the federal EV tax credit).

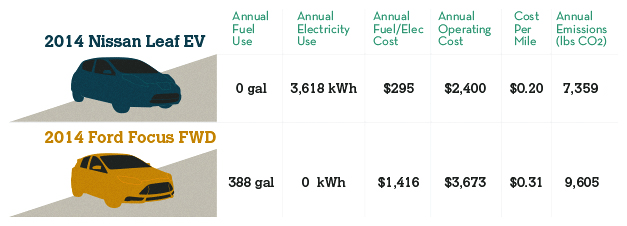

Annual Cost of Ownership

Annual Fuel Use: the amount of fuel excluding electricity (gasoline, E85, diesel, etc.) used by this vehicle in a year. CNG use is in gasoline equivalents (GGE). One GGE of CNG is an amount of CNG that has the same energy content as one gallon of gasoline.

Annual Electricity Use: the amount of grid electricity used by this vehicle in a year. This value will be zero for hybrids or other vehicles that do not plug in.

Annual Fuel/Electric Cost: the cost of all fuel used by this vehicle in a year (including gasoline, electricity, or other fuels).

Annual Operating Cost: the first year operating costs (including fuel, tires, maintenance, registration, license, and insurance).

Cost Per Mile: first year operating costs (including fuel, tires, maintenance, registration, license, and insurance) per mile traveled.

Annual Emissions (lbs CO2): Amount of greenhouse gases emitted by this vehicle in a year.

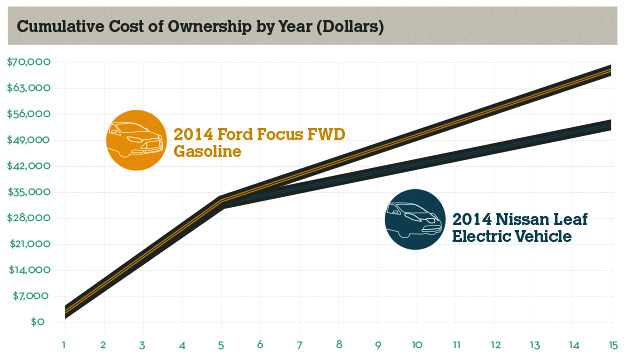

There are many factors to take into account when looking at cost of ownership: upfront expenses, fuel, maintenance, financing, and longevity. After considering these factors, I’ve found that in many cases a person ends up saving thousands, if not tens of thousands, with an electric rather than a gas car. The payback time can be as short as two to three years, and it’s almost always within five years.

Source: Cost of Ownership

Cumulative Cost of Ownership by Year Assumptions

The featured graph shows the cumulative cost of ownership by year for each vehicle, including fuel, tires, maintenance, registration, license, insurance, and loan payment. The tool used to generate the graph assumes a five-year loan with a 10 percent down payment. Year one on the graph represents the 10% down payment plus the first year’s total operating costs. For more information about the information used, visit the Alternative Fuels Data Center website

However, that’s not the end of the money story. Think about it: the cell phone you bought 10 years ago was much different than the one you have today. In a few years, gasoline will be more expensive and electric car technology will be much cheaper. Electric cars will be much better and more cost-competitive in five years than they are today.

Global Benefits

Let’s not forget that electric cars have broader advantages than those that benefit just the individual owner. They cut our dependence on oil, and thus reduce our need to defend oil supplies in foreign nations. They don’t create any direct pollution or global warming emissions compared to conventional vehicles. In addition, there are solar panels available which allow you to drive on sunshine. Reducing oil dependence, air pollution, water pollution, global warming, and their myriad associated problems is something many people genuinely care about. This makes the switch to electric cars that much easier and more logical.

Supply & Demand

It’s worth noting that the technology behind electric cars is fairly new. Costs are coming down rapidly. As more people buy them, manufacturing processes will improve and there will be economies of scale that drive down costs. It’s a virtuous circle. In the case of gasoline-powered cars, the price of oil and gasoline, which are limited resources, will continue to increase.

Back when gasoline cars started to take over the market from electric cars, people like Henry Ford’s wife stuck with their electric cars because of how easy, convenient, and pleasant they were to drive. Thanks to wonderful advances in batteries, as well as improvements in automotive technology, we’re again entering a period where people will choose electric over gas. Eventually, the tables will turn again and gasoline cars will be the historic oldies that few people have ever driven.

*I’m using "electric cars" inclusively in this article in order to include plug-in hybrid electric cars and extended-range electric cars as well as 100% electric cars.

Embed the article on your site